Freeform Technology supports ebalta Distribution in the design and manufacture of an interactive model for the Composite Engineering 2016 show.

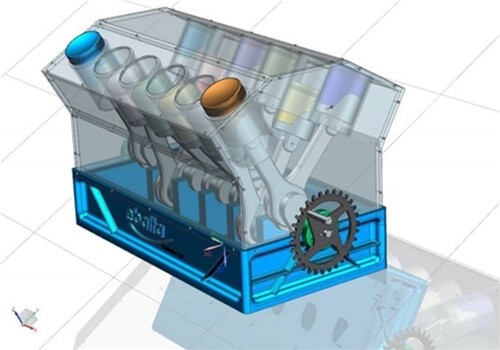

Freeform Technology has trusted ebalta to supply their composite tooling materials from the very first day they began trading in 2008. Since then Freeform has supplied the composite tooling market with first class composite tooling solutions backed up with a supplier of materials that never lets them down. Having seen their 2015 Composites Show model it was a natural decision to ask Freeform’s Director Simon Burchett if they would like to offer their services to design, model and manufacture the main exhibit for the Composites 2016 show at the NEC in Birmingham. Freeform accepted the challenge and after being given the ‘interactive’ brief by ebalta Distribution they designed a V12 engine produced with materials all available from ebalta Distribution on a next day delivery service. Each of the piston heads are removable and interchangeable allowing the show’s visitors to gain information on the surface finish and weight of each material.

Having a history in Formula 1 along with other high pressure and demanding clients, Freeform understands the need to deliver components and composite tooling solutions to a strict deadline with no compromise on quality. Focusing on their customer’s requirements, they can evaluate the projects they are working on, determining if it is possible to improve the specification and provide customers with better value. The shop floor at Freeform has an open and facilitative culture of continuous improvement that encourages creativity without compromising quality, safety and delivery.

Freeform Technology has achieved ISO 9001 certification ensuring our commitment to excellence and continual improvement to meet the needs and demands of their ever expanding customer base.

Freeform Technology was established in 2008 and has grown to become one of the UK’s leading pioneers in 5 axis composite pattern and mould machining techniques.

Simon Burchett said, “Having used most of the composite tooling and modelling boards in the ebalta range we knew we would be able to design, machine and assemble the model with moving components that would stand up to visitors handling the finished products along with the mechanical requirement for the model to operate”.

Freeform Technology is not exhibiting at this year’s show but the model can be found on the ebalta Distribution stand M162 in the composites hall where ebalta will be presenting the complete range of tooling and component, epoxy and polyurethane materials available from ebalta Kunststoff GmbH.

- ebablock P185 (Model Base)

- ebaboard 105

- ebaboard 140

- ebaboard PW920

- ebaboard W

- ebaboard 60-1

- ebaboard 0700

- ebaboard L-1

- EP978

- TB650

- TC460

- ebaboard 1190 Black

All the materials for the model were supplied by ebalta Distribution Ltd which has an extensive range of materials for a variety of other applications including, Foundry Tooling, Composites and Automotive markets.

If you have a project that you would like to discuss, please contact the ebalta Distribution sales team who will be more than happy to meet and discuss how their range can assist you. ebalta’s highly trained staff also provided technical advice in both material selection and processing/machining of the materials.

Paul Reynolds Managing Director at ebalta Distribution states “We have an extensive range of products and offer a great technical service to all our customers. It’s great to see that all come together and see the quality of models being produced.” – Paul Reynolds (Managing Director) [email protected]

If you would like to find out more about Freeform Technology’s composite tooling solutions please get in touch with us, we’re happy to help: https://freeformtechnology.co.uk/contact/