Here at Freeform Technology, we design and manufacture composite patterns and moulds. We can work from either drawing, CAD or on occasions from various other data.

We take each of our individual customer’s requirements, working closely with them to develop the necessary bespoke composite mould manufacturing solutions. Producing a design that maps entirely to the requirement. Where processes may be improved, we offer suggestions and adaptations that may be introduced towards our approach to delivering constant improvement in relation to composite mould manufacturing. Cost analysis also forms part of our approach to critical composite pattern design and tooling. We review any potential modifications that can introduce material cost savings, either through increased elegance of design, faster production throughput, or manufacturing efficiencies. We often achieve resultant cost savings for our customers through a broad aggregation brought about by a combination of small changes, which all add up to a significant cost reduction when measured by a per-unit formula. Cost is something we never take our focus off in pursuit of delivering commercial advantage for our customers.

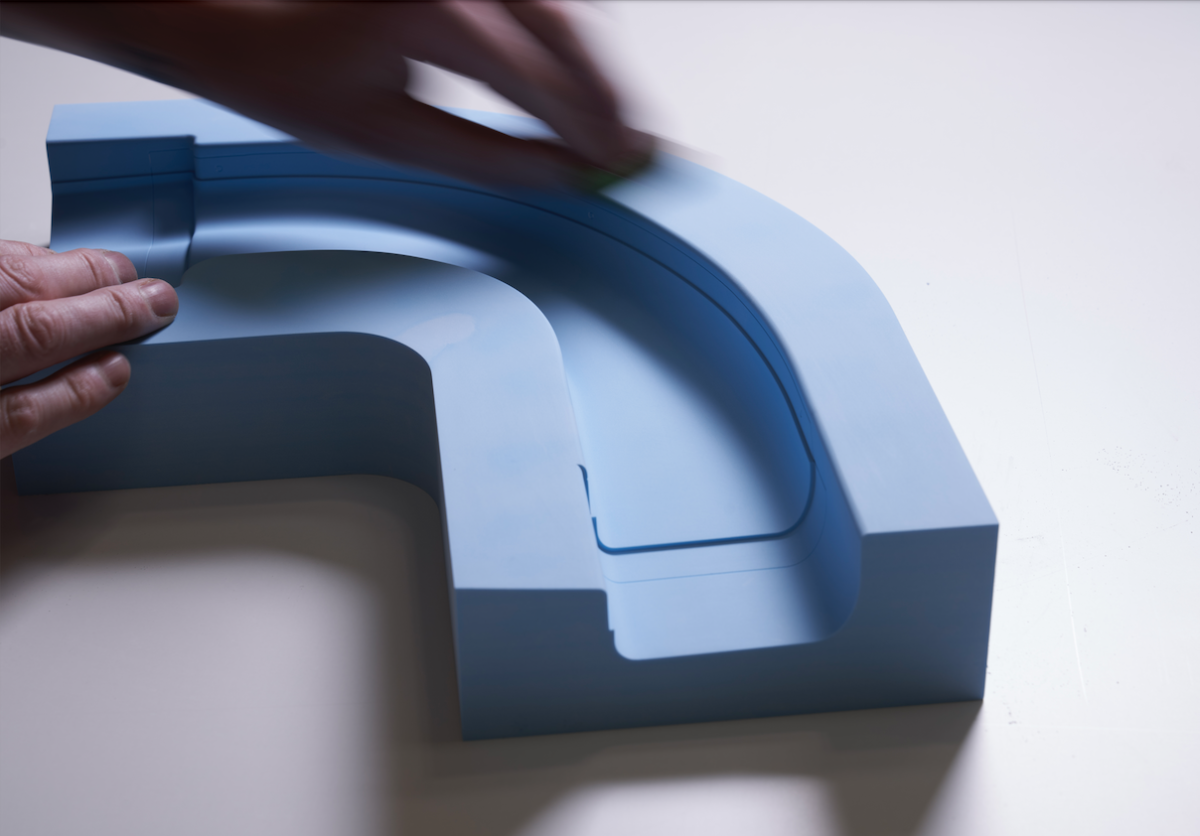

We manufacture to the most complex of requirements and specifications. By using our state-of-the-art machining capabilities, we are able to fully capitalise and leverage the significant investment that we have made in our stable of world-class precision engineering machines for each and every one of our customer projects. Working to the very tightest of tolerances and the highest of standards, we provide our customers with the confidence of execution that Freeform Technology delivers in both expertise, innovation and more. Delivering on time, every time is our ethos.

To understand more about Freeform Technology’s composite mould manufacturing, please get in touch.