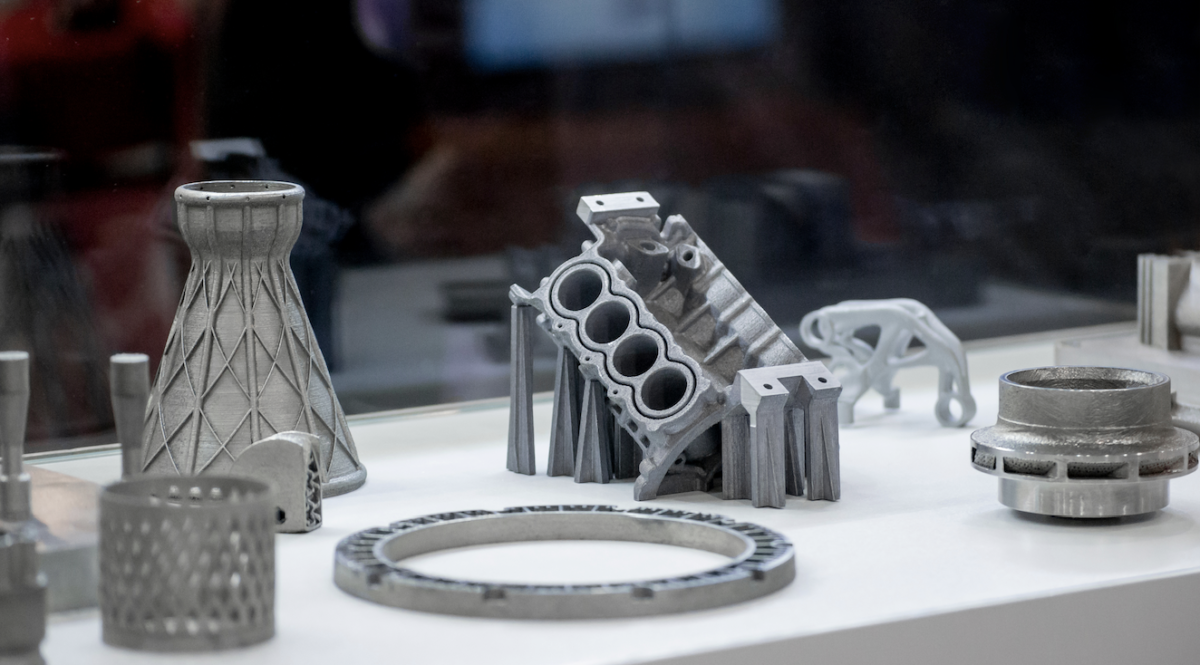

Metal 3D printing is a fusion created by taking complex design capability and converting to an output deliverable that consists of completed tools, components, or tool inserts. This unique and symbiotic fusion facilitates shortened production times, reduced component stress during manufacture, and provides tool life extension.

The very latest advances in Selective Laser Manufacturing (SLM) takes metal 3D printing to new levels.

Technically, our focus here at Freeform Technology is on aluminium and aluminium blends. We produce high quality components through our laser focused obsession to detail in relation to our production methods and measures. Together with this, we have our dedicated team of knowledgeable additive engineering staff. We further complement this with our inspection team who we have invested substantially towards creating the very highest implementation of our quality control processes and practices

One size does not fit all, and the technological advances in metal 3D printing are wide and varied in relation to the wealth of manufacturing possibilities. Some of which can include:

- Fully functional prototypes

- Series production tools

- Tooling (moulds and tool inserts)

- Complex rigid housings

- Ductwork

- Heat exchangers and sinks

But it’s not just technically where the advantages can be found, it’s commercially as well.

The capability of rapid conversion from design concept to prototype, then on to completed finished product tools and components creates the ability to significantly reduce production timelines. This facilitates leveraging the potential benefits for our customers towards execution of any of their go to market strategies. This holds true whether bespoke low volume or commodity high-volume production. Metal 3D printing capabilities, by minimising production times, directly map to the potential of increased profitability through either reduced costs and time used in production or the ability to increase sales volumes – or maybe nirvana – both!

To understand more about how Freeform Technology can support your requirements and for more information please click the button below.