Prototype machining is a tried and trusted early production method that facilitates manufacture of components that are often termed ‘beta’. Beta components enable testing, trialling and evaluation prior to any larger production run or finalised machining of the end-product or component.

By producing an initial machined prototype, costs of early production are minimised whilst simultaneously providing increased scope to change, test or make potential improvements to the original design concept. It’s a win-win, with production start-up costs that are minimised, together with the flexibility of final manufacturing increased. What’s not to like?

We work closely with each of our customers to first and foremost determine their individual list of requirements, and then we subsequently establish a scope of work that matches and delivers to agreed expectations and timelines. Prototype machining by its very nature means developing a very close relationship between ourselves and our customer – from concept and design stage, right through to final production.

We offer virtually unlimited design scope using mock ups, architectural models, displays, templates, reverse engineering, CAD and 3D modelling. Sometimes on rarer occasions, it’s just a conceptual idea in the mind of our customer! We seek to create the art of the possible – from imagination through to reality.

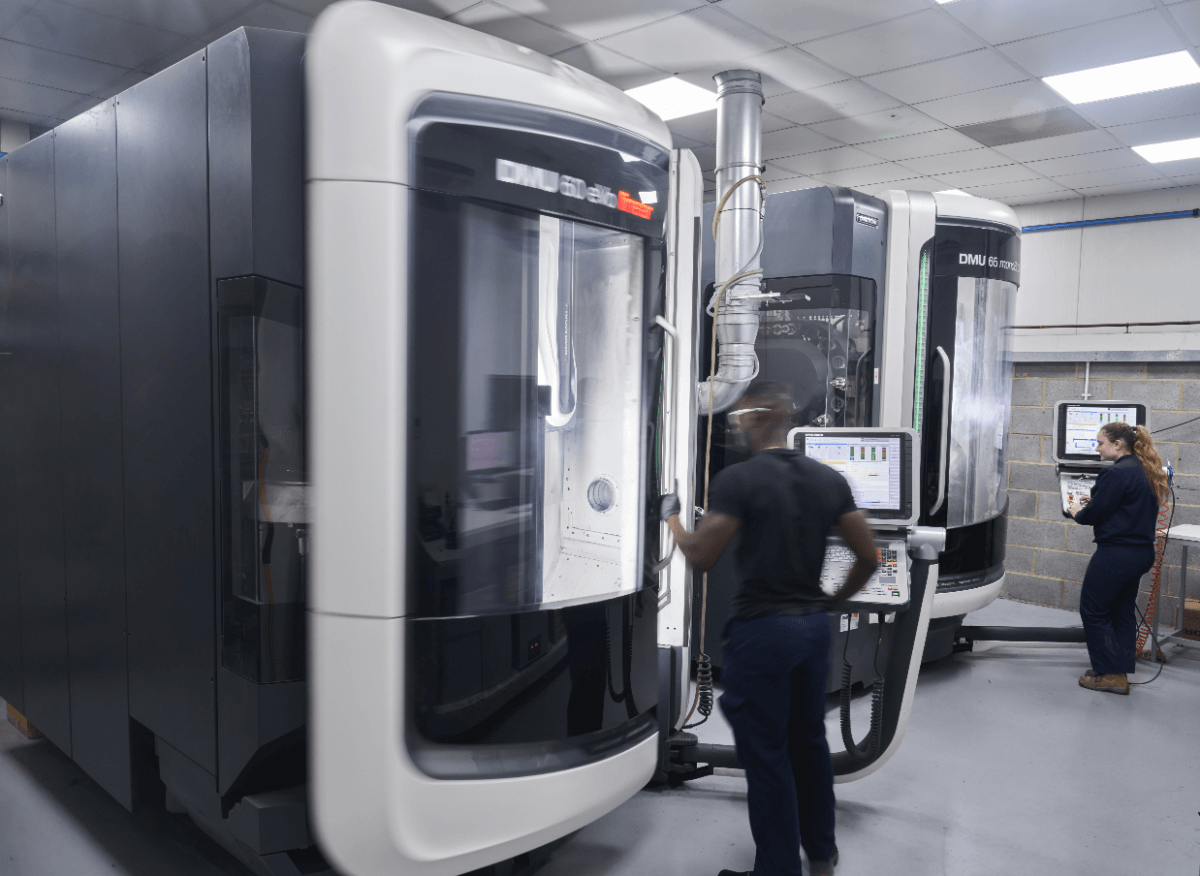

Prototype machining is achieved through our significant investment in state-of-the-art machines and tooling:

- DMU 5-axis centres

- CMS 5-axis routers

- Additive printer

- Extraction units

- Inspection arms

- Sliding table/band saws

This enables us to offer a complete range of comprehensive tooling solutions that facilitate precision manufacture when prototype machining, together with a team of highly skilled staff, motivated in the pursuit of creating individual success for each of our customers.

To understand more about how Freeform Technology can support your requirements and for more information, please click the button below.